Reverse Engineering

In automotive design work, to transmit styling requirements to the engineering design process and on to die making and production, R&D Department uses reverse engineering technology, to ensure that parts exactly match prototype.

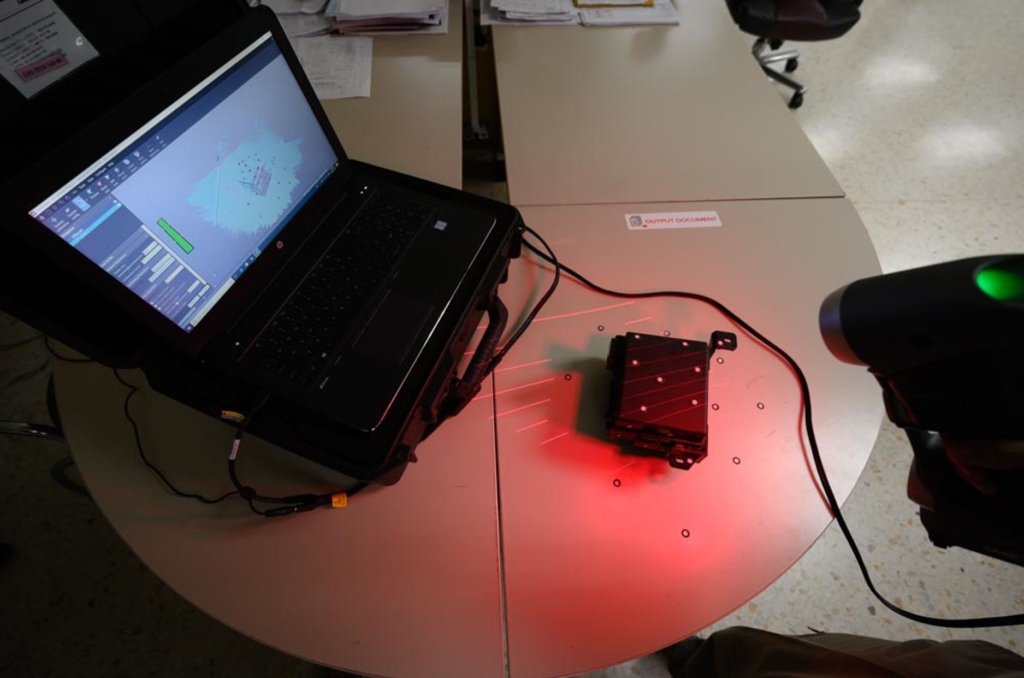

The designer first transfers the design from his imagination to a clay model, and then makes any necessary adjustments. Next we use a 3D Laser scanner to record the surface data of the clay model. The scanner’s arm sweeps over the entire surface of the model and displays the result on a monitor.The scanning machine stores the surface data in digital form and prepares it for transmission to and use in the next step in the design process.

As well as for creating new designs, the equipment can also be used for reverse engineering, whereby production parts are scanned and the resulting surface data compared with the original CAD data from the initial design.

This equipment can also be used for scanning dies to increase productivity or for subsequent care and maintenance

R&D Department uses reverse engineering technology, to ensure that parts exactly match prototype.